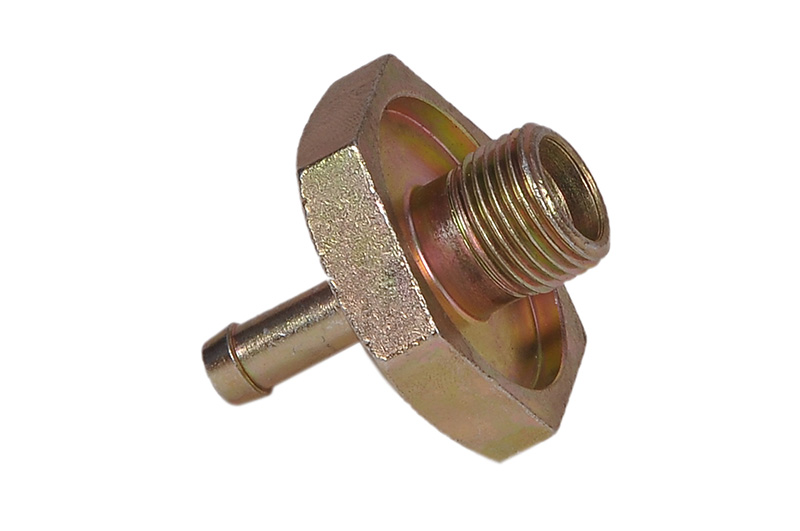

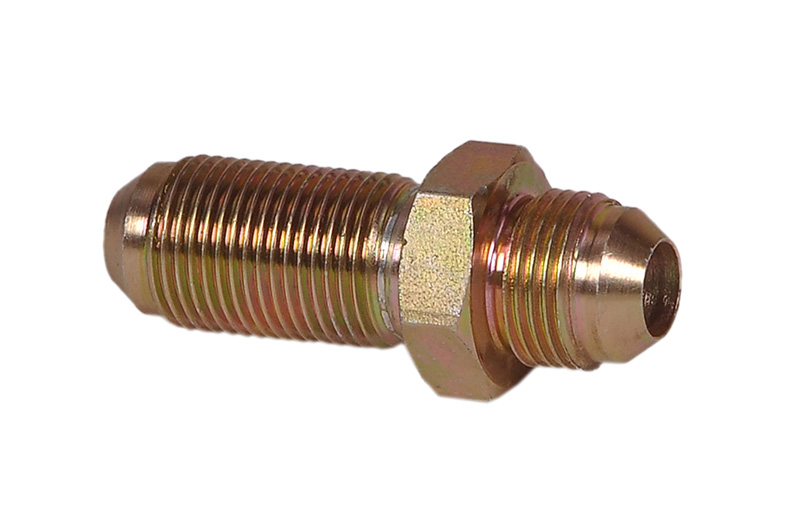

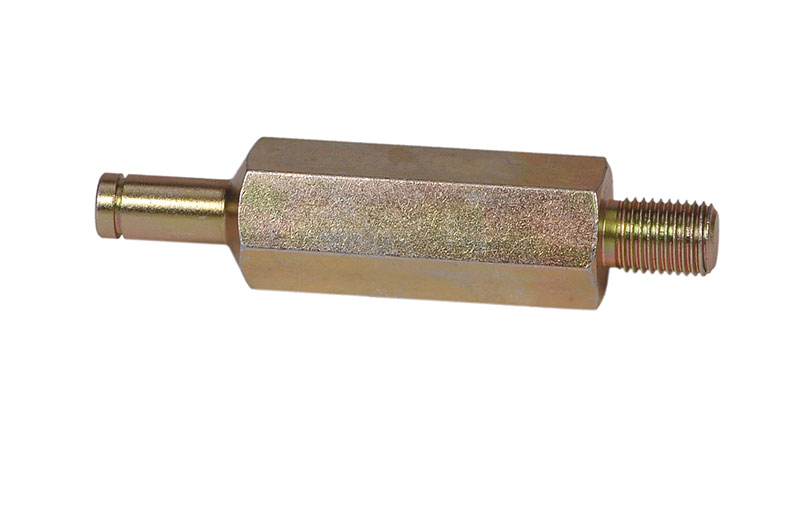

OUR PRODUCTS

OMCO ENTERPRISES: BIGGEST TRACTOR & ENGINE PARTS MANUFACTURER & EXPORTER IN INDIA

OMCO Enterprises is a premier tractor & engine parts manufacturer & exporter in India. In the era of Industry 4.0, we at OMCO Enterprises manufactures precision tractor & engine parts that confirms to the highest global standards. As a leading tractor & engine parts manufacturer & exporter, we utilize the latest technologically advanced machineries to manufacture high-end products. Our skilled and dedicated team of professionals have cross-functional expertise to understand the complete product manufacturing life cycles. Being a popular tractor & engine parts manufacture & exporter in India, we aim to deliver products according to the exact engineering specifications of the OEM’s. We are carrying the legacy for more than 5 decades now catering to various industry verticals like tractor, automobile, Agriculture, Defence, Railways, Electricals and other sectors.

As the popular tractor & engine parts manufacturer & exporter in India, we manufacture precision machined components as per specifications of DIN, BIS, EN, IS, ASTM, AMS, JIS & other International Standards including any tailor-made specifications provided by our esteemed customers.

OMCO Enterprises, which is a reliable tractor & engine parts manufacturer & exporter in India, we manufacture precision machined components, precision turned components, CNC machined components and fabricated components using material grades like En8D, En8, En1A, 20MnCr5, 16MnCr5, En18, En19, SAE4140, SAE 8620, C40, C45, 18CrNiMO7-6, 5.8, 8.8, 10.9, 12.9, Copper, Brass, SS304 etc. which are commonly used. We can also manufacture as per customer specification other than aforesaid grades mentioned above.

Product Specification Matrix

| Standard | DIN, BS, EN, IS, ASTM, AMS, JIS & Other International Standards. |

| Size | Dia 2mm to 200 mm |

| Length | 2 mm to 600 mm |

| Finish | Polished, Ground, Burnished |

| Surface Coating | Zinc, Chrome, Nickel, Pham, Manganese, Dacro and as per tailor made specifications |

Induction Hardening Operation

| Parameter | Range |

|---|---|

| Length | 600 MM |

| Dia | 50MM |

| Depth | 4 MM |

Threading Operation

| Parameter | Range |

|---|---|

| Cut Thread | 12 MM |

| Roll Thread | 25 MM |

Press Shop Operation

| Parameter | Range |

|---|---|

| Tonnage | 10 Ton to 150 Ton |

| Sheet Thickness | 0.8 to 10 MM |

Welding Operation

| Gas Metal Arc Welding (GMAW) |

| Mig Welding with Rotary Table Automatic |

| Mig Welding with Rotary + Linear Motion Automatic |

| Pre-Heating Machine |

| Projection Welding |

Manufacturer and exporter of tractor and engine parts in India, OMCO Enterprises is a familiar name amongst renowned Indian OEM’s and across their global hubs.

OMCO Enterprises which is the best tractor & engine parts manufacturer & exporter in India has been providing reliable manufacturing of tractor and engine parts to the Indian market for more than 5 decades. As a popular tractor & engine parts manufacturer & exporter in India, we are committed to utilizing innovative technologies to manufacture top-notch tractor & engine parts. We manufacture tractor and engine parts in compliance with national and international standards. In order to consistently meet and exceed customers’ expectations, we strive to produce the highest-quality products. We follow industry 4.0 standards to manufacture and export our high-quality products.

Tractor Parts of the Highest Quality

As a foremost tractor & engine parts manufacturer & exporter in India, OMCO Enterprises manufactures tractor parts using a variety of advanced technologies to ensure the highest quality standards. Ultrasonic Washing Testing is one of the top-notch technologies that we use. Ensuring the cleanliness of components, especially those featuring intricate designs or specific details, requires an effective approach to eliminate dirt and debris. This process involves cleaning parts using ultrasonic waves.

To ensure that parts are clean, OMCO Enterprises uses Millipore testing in addition to ultrasonic washing testing. This procedure entails running a fluid through a filter, which isolates any suspended particles in the fluid. The particles that have been captured are then analyzed to determine the cleanliness of the part.

The company added the Digital Height Master from CARLZEISS to its inspection facilities to guarantee the accuracy and precision of the parts. This device uses laser interferometry, a high-precision measuring technique, to measure component heights with a 0.5-micron accuracy. This guarantees that every component is produced to exacting standards, resulting in a consistent level of quality.

Being one of the top tractors and engine parts manufacturers and exporters, OMCO Enterprises takes care of the quality of all the products. A Contour and Roughness Tester is also used by OMCO Enterprises to gauge the surface finish of components. This device assesses the surface quality of components, taking into account factors like surface roughness, waviness, and form. As a result, the parts are guaranteed to have a good aesthetic and a smooth finish in addition to proper functionality.

Engine Parts Manufactured by Premium Quality Materials

As the best tractor and engine parts manufacturer & exporter in India, we understand that an engine is the driving force behind a tractor, converting fuel into actionable energy. Its importance cannot be overstated as an operational tractor without its engine would be rendered immobile and effectively useless. As such, the engine plays a crucial role in successful agricultural operations. Engine blocks, pistons, and crankshafts are just a few of the engine parts that are manufactured by OMCO Enterprises (A Top Tractor & Engine Parts Manufacturer in India). These parts are constructed utilizing premium quality materials and advanced fabrication processes so as to guarantee their dependability and longevity.

Precision casting is one of the advanced technologies used by OMCO Enterprises (trusted tractor & engine parts manufacturer & exporter in India) in the manufacture of engine parts. In order to create the desired shape, the metal is first melted and then poured into a mold. Precision casting guarantees that the components are highly accurate and that they can be produced quickly in large quantities. OMCO Enterprises utilizes computer-aided design (CAD) software for the purpose of creating and optimizing engine components prior to production.

The engine components are subject to rigorous testing to ensure their reliability and performance. OMCO employs a variety of testing procedures, including hydraulic testing, pressure testing, and endurance testing, to make sure that the engine parts can withstand heavy loads and continue to function properly over time. Through this testing, it is made sure that the engine parts are of a quality that meets or exceeds the standards.

Quality Policy

As a leading tractor & engine parts manufacturer & exporter in India, we are dedicated to ensuring customer satisfaction by delivering high-quality products at the appropriate price and within the required time frame, as well as by actively involving staff members at all levels through ongoing development and training. Quality is number one priority for OMCO Enterprises (Tractor & Engine Parts Manufacturer & Exporter in India). As a top-notch tractor & engine parts manufacturer & exporter in India, we follow all the environment & safety measures while manufacturing tractor and engine parts.